Computational fluid dynamics, or CFD, has become one of the most powerful tools in modern fire engineering. It allows designers to simulate how a real fire and smoke might behave inside a specific building, rather than assuming simplified patterns.

When used correctly, CFD helps teams prove safety outcomes for performance based design, especially in large, open, or unusual spaces. It gives architects and builders a scientific way to justify solutions that do not fit neatly into prescriptive codes.

Why CFD matters in performance based fire design

Performance based design asks whether a building will keep occupants safe under credible fire scenarios, not only whether it follows fixed rules. CFD supports this by predicting temperatures, smoke layers, visibility, toxic gas spread, and sprinkler interactions in three dimensional space.

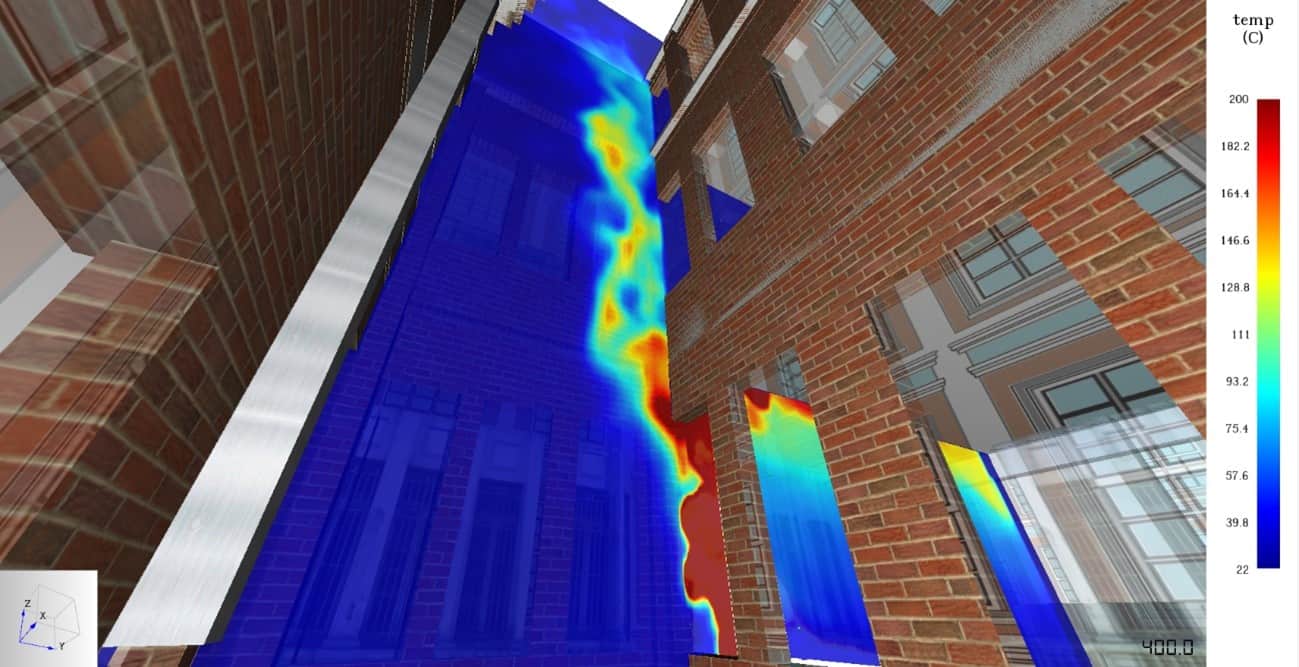

Because the model is tied to the exact geometry and ventilation paths of the project, it can reveal risks that hand calculations miss. For example, smoke may pool under a high roof, flow through an atrium, or leak into adjacent zones depending on openings and pressure differences.

In this context, learn more about CFD modelling fire is not just a topic of curiosity, but a gateway to understanding how digital evidence can support approvals. The simulation results help engineers demonstrate that tenability criteria are met long enough for safe evacuation.

CFD also allows teams to test multiple design options quickly. Instead of building a conservative system for every worst case, designers can explore targeted measures that address the actual behavior predicted for the space.

How CFD fire modelling is carried out

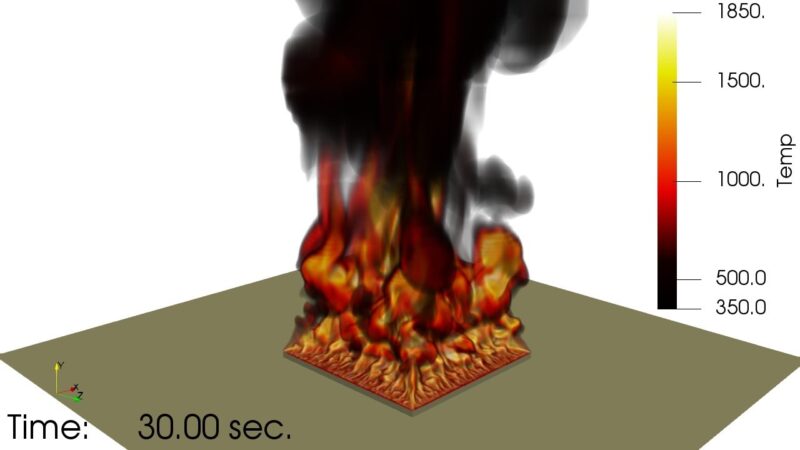

The process begins by defining a set of fire scenarios that reflect realistic ignition sources and fuel loads for the occupancy. Each scenario includes a heat release rate curve, growth profile, location, and duration that represent credible events.

Next, engineers build a digital model of the space, including walls, openings, furniture or equipment that affect flow, and mechanical systems such as smoke exhaust or air handling. The mesh density is chosen carefully, because a coarse mesh can hide important gradients while an overly fine mesh may be impractical to run.

Boundary conditions follow, covering outdoor wind, internal temperatures, leakage paths, and operational assumptions like door positions or fan activation timing. These inputs must be documented clearly because they shape the reliability of the results.

The CFD solver then calculates fluid motion, heat transfer, and combustion products over time. Outputs are compared against acceptance criteria such as minimum visibility on egress routes, maximum temperature at head height, and limits for carbon monoxide and other toxic species.

Finally, engineers interpret the results with professional judgment, checking for model stability and performing sensitivity checks. It is common to run variations of key inputs to confirm conclusions remain safe even if conditions shift.

Design decisions CFD can justify

One of the most common uses is smoke control design. CFD can show whether a specific exhaust rate keeps a smoke layer above occupants, or whether additional vents or makeup air paths are needed.

It is also used to refine egress strategies. By predicting how smoke affects corridors, stairs, and refuge areas, CFD helps determine if travel distances, exit widths, or phased evacuation plans are sufficient.

Structural fire engineering benefits as well. CFD derived temperature fields can be fed into structural models to prove that beams, columns, or timber members retain strength for the required time without excessive protection.

Large atriums, transport hubs, warehouses, and mixed use developments often rely on CFD to permit openness that traditional compartment rules would restrict. The same applies to innovative materials or facade systems where real heat and smoke exposure must be understood.

When results show a risk, the model guides focused mitigation instead of broad upgrades. Designers might add a smoke curtain, relocate an opening, strengthen detection, or adjust sprinkler zoning to solve the specific issue.

Conclusion

CFD fire modelling gives performance based design a realistic view of how fire and smoke behave in a particular building. By testing credible scenarios and linking results to safety criteria, it helps teams create flexible designs that remain demonstrably safe and easier to approve.